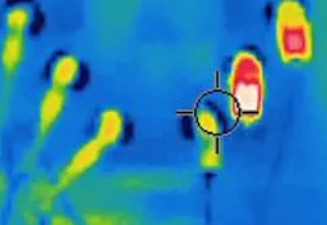

Infrared testing

It’s amazing what lightning and overload can do to your system. An infrared scan will find these problems before an outage does.

- Overloaded Transformers

- Hot elbows

- Hot elbow arrestors

- Hot secondary wires and blocks

- Undersized neutrals

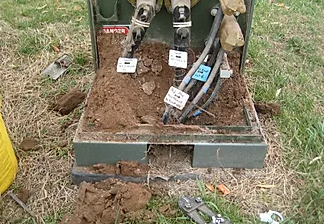

Repairs/Maintenance

Lets face it, overtime things happen to URD equipment. While at the cabinet location, our technicians can correct many of the problems a cabinet has.

- Repair/replace locking assemblies and penta assemblies

- Patch holes in fiberglass or metal basements and cabinets

- Stop transformers from leaking oil

- Clear brush and obstructions

- Clean inside of cabinets filled with dirt

- Ground resistance test (OHM)

- Change warning, danger and ID # stickers

- Install locator bond to outside of cabinet

- Install fiber optic or telephone bonds to utility ground

- Leveling

- Concrete protective post installation

- Install/replace cable route markers

- Install/replace reflective location markers

- Add grounds to bring cabinet to code

- PCB oil test

- Fill sunken cable trenches or washouts

- Tag elbows & secondaries

- Stray voltage test

- Install secondary block covers

Report maintenance items

When a problem is found, good documentation is key to remedying the problem in the most effecient way possible. Our reports can come with real time GPS coordinates and a photo of the issue attached right to the record. This way, the linecrew can view the problem before leaving the shop, taking the guess work out of “what to bring” out in the field.

- Elbows backing off bushings

- Swollen elbows

- Hot elbows and arrestors

- Corroded grounds

- Improperly grounded equipment

- Equipment sunk or located in a dangerous location

- Customer obstructions prohibiting proper operating-clearance

- Underground protective caps

- Y splices

- Mapping errors